Why Ship Excavators and Bulldozers from China?

How to ship excavators and bulldozers from China has become a strategic decision for many global buyers in construction and mining sectors. With its vast manufacturing base, China provides competitive pricing and wide availability of heavy equipment—from mini excavators to full-scale bulldozers.

Chinese manufacturers like SANY, XCMG, Zoomlion, and Shantui have significantly improved in terms of product quality and global distribution. Whether you’re a contractor in Africa, a dealer in the Middle East, or a government project manager in South America, sourcing from China can reduce procurement costs and lead times.

However, international shipping of large industrial equipment comes with its own set of challenges. The size, weight, and handling requirements of such construction machinery demand specialized logistics planning. Choosing the right shipping method—whether it’s Ro-Ro, Break Bulk, or containerized options—is critical to avoid costly delays, damage, or unexpected expenses at the destination port.

In this guide, we’ll walk you through the best practices, options, and real-world considerations for shipping from China to your project site safely and efficiently.

Available Shipping Methods for Excavators and Bulldozers

When it comes to shipping heavy equipment like excavators and bulldozers from China, selecting the right shipping method is crucial. These machines are typically classified as oversized cargo or specialized equipment, which means they require tailored transport solutions beyond standard container shipping.

Here are the four primary options:

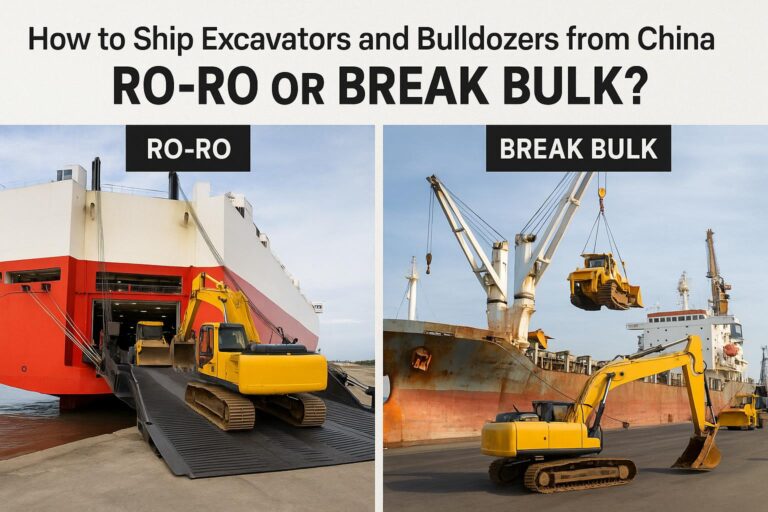

Ro-Ro Shipping (Roll-on/Roll-off)

This method involves driving self-propelled machinery directly onto a RoRo vessel. It’s ideal for mobile, intact units like wheeled excavators or bulldozers that can be rolled on and off with minimal handling.

Best for: Operational equipment in working condition

Handled by: Specialized shipping companies with access to RoRo terminals

Pros: Faster loading/unloading, reduced damage risk

Cons: Not suitable for dismantled or non-moving machines

Break Bulk Shipping

For large, static, or disassembled machines, breakbulk shipping is often the best solution. Equipment is lifted onto the vessel as individual pieces and secured on deck or below deck using cranes.

Best for: Oversized, irregular, or heavy-duty components

Common in: Mining, construction, and infrastructure projects

Requires: Specialized handling and careful planning

Flat Rack Containers

A flat rack is a type of open container with collapsible sides, used to load equipment that exceeds standard height or width limits. Excavators with booms attached, or bulldozers with blades, are often shipped this way.

Best for: Partially oversized machines that still fit within container shipping dimensions

Additional needs: Blocking, bracing, and proper securing for ocean movement

Open Top Containers

These are ideal for machinery that is slightly taller than standard containers. The roof is removed to allow top-loading using cranes.

Useful for: Tall excavators or attachments

Lower cost than flat racks, but may have height limits depending on the port

Each of these methods has different requirements in terms of port facilities, equipment handling, and transit conditions. Working with an experienced freight forwarder will ensure you select the most suitable method based on your cargo size, shipping destination, and budget.

Ro-Ro Shipping: Advantages and Limitations

Ro-Ro shipping—short for Roll-on/Roll-off—is one of the most popular ways to transport wheeled cargo like excavators and bulldozers. This method involves driving the machinery directly onto the RoRo vessel, where it is securely parked and later rolled off at the destination port.

Advantages of Ro-Ro Shipping

Minimal Handling: Since machines are not lifted by cranes, the risk of damage during loading and unloading is significantly reduced.

Faster Turnaround: Ro-Ro offers quicker loading and discharge compared to breakbulk, making it ideal for time-sensitive deliveries.

Cost-Effective Method: For fully assembled, mobile machinery, Ro-Ro is often more affordable than breakbulk or flat rack options.

Regular Schedules: Most major shipping lines operate consistent Ro-Ro services from China to ports in the Middle East, Africa, Europe, and South America.

Reduced Risk of Delays: Simple operations and efficient logistics processes help to avoid costly delays at ports.

Limitations of Ro-Ro Shipping

Only for Mobile Units: Ro-Ro requires the equipment to be in working condition—non-operational or disassembled machines are not eligible.

Exposure to Weather: While RoRo decks are generally enclosed, some equipment may be parked in open areas depending on space availability.

Not Suitable for Oversized Equipment: Machinery exceeding certain dimensions may not fit into the Ro-Ro decks and would need to be shipped via breakbulk or flat rack.

Ro-Ro remains the top choice when shipping brand-new or fully operational used equipment. It offers a blend of speed, safety, and cost savings—provided your machine can literally “roll” on and off the vessel.

Break Bulk Shipping Explained

When Ro-Ro shipping isn’t suitable—such as when the machine is non-functional, disassembled, or exceeds Ro-Ro size limits—breakbulk shipping becomes the go-to solution. This method is widely used for transporting heavy cargo, oversized freight, and large-scale industrial equipment that cannot be containerized.

What Is Break Bulk Shipping?

Breakbulk shipping (also known as breakbulk freight) refers to the process of loading individual items directly onto the vessel without the use of containers. Each item—such as a disassembled bulldozer, excavator boom, or counterweight—is secured with heavy-duty lashing and lifted aboard using dockside cranes.

When to Use Break Bulk:

The machinery is too large or irregularly shaped for standard or open-top containers

Equipment is disassembled for transport (e.g., tracks, booms, and blades shipped separately)

Units are non-self-propelled and cannot be rolled onto a Ro-Ro vessel

You’re shipping multiple pieces of specialized equipment as bulk shipping cargo

Pros of Break Bulk Shipping:

No Size Constraints: Easily handles cargo beyond container or Ro-Ro limits

Versatility: Suitable for both new and used equipment, including damaged or retrofitted units

Ideal for Project Cargo: Often used in energy, mining, and construction projects involving large scale cargo

Cons to Consider:

Higher Shipping Costs: Due to labor-intensive loading and specialized handling requirements

Longer Port Operations: Breakbulk loading and unloading take more time and may face scheduling delays

More Exposure to Risk: Items may be handled multiple times, requiring expert supervision to avoid damage

Break bulk is often chosen for large earthmoving machinery, complex construction rigs, and oversized cargo that simply doesn’t fit traditional transport categories. Partnering with an experienced freight forwarder who understands breakbulk cargo logistics is critical to ensuring a safe and smooth operation.

Flat Rack & Open Top Containers for Oversized Freight

Not all excavators and bulldozers qualify for Ro-Ro or breakbulk shipping. When machinery dimensions slightly exceed standard container limits—or when partial disassembly is acceptable—flat rack and open top containers offer practical alternatives.

These options are part of container shipping, which can reduce costs and simplify port handling for certain types of oversized freight.

Flat Rack Containers

Flat rack containers have collapsible sides and no roof, designed for loading heavy and wide machinery from the top or sides. They’re commonly used for:

Excavators with arms or booms attached

Bulldozers with wide blades

Equipment parts that need specialized handling

Advantages:

Compatible with standard container terminals

Easier loading and unloading with cranes or forklifts

Can be stacked and shipped alongside standard containers

Limitations:

Height and width still have limits imposed by port and vessel restrictions

Requires proper securing with steel chains, wooden blocks, and lashings

May face additional charges at ports for out-of-gauge cargo

Open Top Containers

Open top containers are similar in size to standard 20ft or 40ft units but lack a fixed roof, allowing cargo to be lifted in vertically. This is ideal when:

Equipment height exceeds the container door height

Top-down loading and unloading is needed

The machine has unusual top attachments (e.g., exhaust stacks or cabs)

Use Cases:

Mini bulldozers with raised blade positions

Small excavators with fixed boom height

These containerized options are often more cost-effective than breakbulk—if the equipment fits within allowable limits. They also simplify customs clearance and documentation, as containerized freight is more standardized across global shipping lines.

Cost of Shipping Excavators and Bulldozers from China

The cost of shipping heavy equipment like excavators and bulldozers from China depends on several variables, including the shipping method, equipment size, port of discharge, and whether the machinery is disassembled or self-propelled.

Below is a general estimate of shipping costs for various transport modes in 2025:

Shipping Method | Cargo Type | Destination Region | Estimated Cost (USD) | Transit Time |

|---|---|---|---|---|

Ro-Ro Shipping | Self-propelled bulldozer | Middle East (e.g. Jebel Ali) | $1,800 – $2,600 | 25–30 days |

Break Bulk Shipping | Dismantled excavator (35 tons) | Africa (e.g. Lagos) | $3,500 – $5,000 | 35–45 days |

Flat Rack | Medium-size crawler excavator | South America (e.g. Callao) | $2,200 – $3,800 | 30–40 days |

Open Top Container | Compact bulldozer (partially disassembled) | Southeast Asia (e.g. Manila) | $2,200 – $3,000 | 15–22 days |

Note: These rates are indicative and vary based on port congestion, fuel surcharges, peak season demand, and local handling fees.

What Affects the Final Shipping Cost?

Size and Weight: The larger and heavier the machine, the more expensive the shipping.

Port Fees & Documentation: Each port has its own tariff structure, especially for oversized cargo or specialized equipment.

Loading and Unloading Complexity: Machinery requiring cranes, dismantling, or custom lashing increases handling fees.

Customs Clearance Costs: Duties, taxes, and brokerage fees at the destination impact total landed cost.

How to Minimize Costs and Avoid Surprises

Work with an experienced freight forwarder who specializes in heavy machinery and project cargo

Choose the most cost-effective method based on your machinery’s condition and final destination

Book early to secure better shipping rates, especially during peak season (Q2–Q3)

Required Documents and Customs Clearance

Successful customs clearance is essential when shipping excavators and bulldozers from China. These are high-value, regulated items that require precise documentation to avoid delays, penalties, or cargo holds at the destination port.

Essential Export Documents from China

Commercial Invoice

Lists the buyer, seller, machinery description, HS code, and declared value

Must match the Bill of Lading and Packing List

Packing List

Detailed breakdown of parts (especially for disassembled units)

Includes dimensions, weight, and packaging type

Bill of Lading (B/L)

Issued by the shipping company or freight forwarder

Serves as proof of cargo receipt and shipping contract

Certificate of Origin (CO)

Required by many customs authorities for preferential tariffs

Issued by the China Council for the Promotion of International Trade (CCPIT)

Export Customs Declaration

Filed electronically with Chinese customs using the proper Harmonized Tariff Schedule (HTS) code

Excavators and bulldozers typically fall under HS Code 8429.xxxx

Destination Clearance Requirements

Upon arrival at the port, your customs broker or consignee must:

Present the full documentation set

Declare the cargo using correct local HTS code

Pay import duties and VAT as required

Ensure the machine meets customs regulations (e.g., emissions standards, certifications)

Some countries may require additional permits, especially for used construction machinery or mining equipment. In such cases, hiring a licensed customs broker is strongly recommended to ensure smooth clearance and compliance with all import rules.

Pro Tip: Minor documentation errors—such as mismatched values, missing engine serial numbers, or incorrect HS codes—can lead to shipment delays and unexpected fines.

Choosing the Right Freight Forwarder

Selecting the right freight forwarder is one of the most important decisions when shipping excavators and bulldozers from China. These are not small parcels—they’re heavy equipment, often classified as project cargo, requiring specialized planning, permits, and port coordination.

A qualified experienced freight forwarder doesn’t just book a space on a vessel. They manage the entire logistics process, ensuring that every step—from loading at the Chinese factory to final delivery at your project site—is executed with precision.

What to Look For in a Heavy Equipment Freight Forwarder:

Experience with Oversized Cargo:

Look for companies with a proven track record in shipping construction machinery, mining equipment, or industrial equipment.Multimodal Expertise:

Can they combine sea freight with road or rail to reach inland sites?Customs Knowledge:

They should assist with proper documentation, HS code classification, and customs clearance both in China and at the destination.Risk Management:

Ensure your forwarder offers cargo insurance options and understands how to minimize risks during loading and unloading.Transparent Communication:

You need real-time updates, clear rates, and advice on the most cost-effective method to move your machinery.

How a Good Forwarder Ensures Smooth Delivery

An experienced partner will coordinate:

On-site pickup from the Chinese manufacturer or warehouse

Arrangement of specialized handling for oversized units

Booking with reliable shipping lines or RoRo vessels

Real-time tracking and proactive updates

Customs liaison and delivery to the final destination

Partnering with the right forwarder means fewer delays, reduced damage risk, and greater cost savings in the long term—especially for complex or high-volume shipments.

Major Destination Ports and Transit Time

Shipping excavators and bulldozers from China to overseas markets involves navigating complex international trade routes. Transit time varies depending on the shipping method, port location, and carrier schedule. Below are some of the most common destination ports and average shipping times for heavy equipment.

Middle East

Popular Ports:

Jebel Ali (UAE)

Dammam (Saudi Arabia)

Sohar (Oman)

Estimated Transit Time:

Ro-Ro or Break Bulk: 20–30 days from major Chinese ports like Shanghai, Tianjin, or Guangzhou

Containerized Shipping: 18–25 days

This region is highly active in construction and infrastructure, making it a frequent recipient of bulldozers, excavators, and industrial equipment from China.

Africa

Popular Ports:

Mombasa (Kenya)

Lagos (Nigeria)

Tema (Ghana)

Durban (South Africa)

Estimated Transit Time:

Break Bulk or Ro-Ro: 30–45 days

Container Shipping: 28–40 days

Africa’s booming mining and road construction sectors drive strong demand for heavy equipment imports.

South America

Popular Ports:

Estimated Transit Time:

Ro-Ro or Break Bulk: 35–50 days

Container Shipping: 33–45 days

Due to longer distances and fewer direct routes, shipping costs may be higher, and booking through an experienced forwarder is recommended.

Southeast Asia

Popular Ports:

Manila (Philippines)

Ho Chi Minh City (Vietnam)

Jakarta (Indonesia)

Estimated Transit Time:

Container Shipping: 10–18 days

Ro-Ro (limited routes): 12–20 days

Shorter distances mean faster international shipping, often with flexible options for flat racks or open tops.

Tip: Knowing your destination port’s equipment handling capacity is crucial—some ports may not support Ro-Ro or breakbulk, requiring a shift in strategy.

Final Delivery and Local Handling

Once your excavators or bulldozers arrive at the destination port, the shipping process enters its final—but equally critical—phase: final delivery and local handling. This step can involve significant logistical coordination, especially if you’re dealing with project cargo or shipping to remote job sites.

What Happens After Port Arrival?

Unloading from Vessel:

Whether your equipment arrives via Ro-Ro, breakbulk, or container shipping, local stevedores handle unloading processes using cranes or ramps, depending on cargo type.Customs Clearance:

If not pre-arranged by your freight forwarder, a local licensed customs broker must complete import formalities, including duties, inspections, and local customs regulations.Storage at Port or Inland Yard:

Depending on availability, equipment may be temporarily stored at a bonded warehouse or container depot while awaiting last-mile transport.Inland Delivery:

Bulldozers and excavators are usually trucked to the final destination using:Low-bed trailers for non-roadworthy or oversized equipment

Roll-off trucks for driveable units arriving via Ro-Ro

Risks and How to Avoid Them

Shipment Delays: Incomplete paperwork or unpaid port fees can cause demurrage charges or extended port holds

Damaged Cargo: Improper handling of valuable cargo—especially during unloading—can result in operational issues or repair costs

Inaccessible Sites: Remote or mountainous areas may require special transport permits or alternative routing

Ensuring Smooth Delivery

To minimize risks and ensure a smooth delivery, always:

Confirm destination logistics requirements before shipping

Provide detailed delivery addresses, access info, and local contacts

Choose a forwarder who offers end-to-end service, including inland delivery and unloading support

Conclusion: Which Method Is Best for Your Machinery?

Choosing the right shipping method for your excavators or bulldozers depends on several key factors—equipment condition, dimensions, destination port capabilities, and your project timeline.

Here’s a quick breakdown to help you decide:

Equipment Type | Recommended Shipping Method | Why? |

|---|---|---|

Self-propelled, mobile machinery | Ro-Ro Shipping | Fast, low-risk loading, ideal for smooth delivery |

Disassembled, oversized equipment | Break Bulk Shipping | No dimensional limits, perfect for specialized equipment |

Slightly oversized but containerizable | Flat Rack / Open Top | Lower cost than breakbulk, easier port handling |

Small to mid-size units | Standard Container (if fits) | Most cost effective and commonly accepted |

Ultimately, the most suitable shipping process is the one that balances reliability, budget, timing, and local infrastructure. There’s no one-size-fits-all solution, especially when handling heavy equipment.

Working with a specialized freight forwarder ensures you don’t just move cargo—you deliver value, avoid delays, and meet your project goals with confidence.

Frequently Asked Questions (FAQs)

Can I ship non-operational excavators via Ro-Ro?

No. RoRo shipping requires the machinery to be self-propelled and in working condition. If your equipment is non-operational or partially disassembled, you’ll need to use breakbulk freight or flat rack container shipping instead.

What documents are required for customs clearance?

You’ll need a commercial invoice, packing list, bill of lading, certificate of origin, and export declaration. For customs clearance at the destination, a licensed customs broker will also classify your cargo using the correct Harmonized Tariff Schedule (HTS) code and handle import duties.

What’s the average cost of shipping an excavator from China?

Depending on size, method, and destination, the cost of shipping ranges from $2,200 to $6,000 per unit. RoRo shipping is generally more affordable for mobile machines, while break bulk is more costly due to labor-intensive handling.

Can bulldozers be shipped inside a standard container?

Small or compact bulldozers may fit inside a 20ft or 40ft standard container, especially when partially disassembled. Larger units typically require open top containers or flat racks to handle oversized cargo.

How do I choose the best freight forwarder for heavy equipment?

Look for a freight forwarder with proven experience in heavy machinery shipping, a solid understanding of international shipping regulations, and end-to-end capabilities—from factory pickup to final delivery.

What are the transit times for major regions?

Middle East: 20–30 days

Africa: 30–45 days

South America: 35–50 days

Southeast Asia: 10–18 days

These vary by port, shipping method, and carrier schedules.

Can I minimize cost without sacrificing reliability?

Yes. Choosing the right shipping method, consolidating cargo, and working with an expert freight forwarder can result in major cost savings while ensuring smooth handling throughout the shipping process.